What We Supply

At Silian Capital, we specialize in providing high-quality industrial equipment and comprehensive solutions tailored to meet the needs of diverse industries. Our offerings support critical processes in sectors such as energy, manufacturing, chemical production, and logistics, ensuring maximum operational efficiency, safety, and long-term reliability.

We deliver not just equipment, but integrated solutions designed to streamline operations, enhance performance, and optimize productivity. With a focus on cutting-edge technologies and a global network of trusted manufacturers, Silian brings together top-tier products, engineering expertise, and exceptional service to address the most demanding industry challenges.

Whether you are expanding your production capacity, upgrading equipment, or implementing new technologies, Silian provides the reliable tools you need to drive success and stay competitive in a rapidly evolving market.

EQUIPMENT

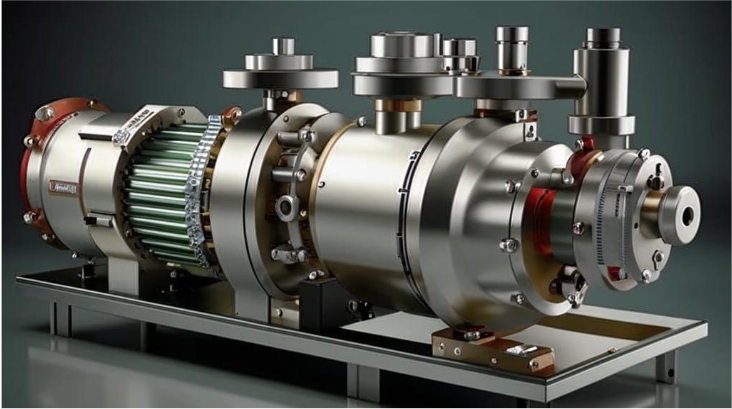

Pumps & Pumping

Industrial pumps play a critical role in moving fluids through pipelines and processing systems. They are designed to handle a wide range of liquids — from clean water and corrosive chemicals to viscous slurries and hydrocarbons.

Depending on the process requirements, pumps come in different types such as centrifugal, diaphragm, screw, or gear pumps, each providing specific flow rates, pressure levels, and compatibility with challenging environments. Efficient pumping ensures process stability, energy savings, and reduced maintenance downtime.

Common Applications:

Pumps are widely used in oil and gas operations for transferring crude, injecting chemicals, and circulating drilling fluids. In the chemical industry, they handle aggressive and high-viscosity substances. Power plants use pumps for cooling and boiler feed systems, while water treatment facilities rely on them for filtration and distribution. In the food and beverage sector, pumps ensure sanitary and precise handling of liquid ingredients.

EQUIPMENT

Valves & Flow Control

Valves are essential for regulating the flow, pressure, and direction of liquids and gases in industrial systems. From simple shut-off functions to automated flow control, they ensure safe and efficient operations across a wide range of sectors.

This category includes gate, globe, ball, butterfly, and check valves, as well as pressure relief valves, actuators, and control systems. Designed for durability and precision, they are used in oil & gas, power, chemical processing, water treatment, and manufacturing.

Common Applications:

Valves and flow control systems are widely used in industries that handle liquids and gases. In oil & gas, they manage flow in pipelines and refineries; in chemical plants — ensure safe handling of aggressive substances. Power plants use them for steam and cooling systems, while water treatment and food industries rely on them for precise and hygienic fluid control. Their role is key in maintaining safety, efficiency, and process reliability.

EQUIPMENT

Heat Exchangers

Heat exchangers are essential for transferring thermal energy between fluids without mixing them. These systems help regulate temperatures in industrial processes, improve energy efficiency, and protect sensitive equipment from overheating. Available in various designs — plate, shell-and-tube, and air-cooled — they are tailored to specific operational pressures, flow rates, and fluid types. Reliable heat exchange ensures stable performance, process safety, and cost-effective energy use.

Available in various designs — plate, shell-and-tube, and air-cooled — they are tailored to specific operational pressures, flow rates, and fluid types. Reliable heat exchange ensures stable performance, process safety, and cost-effective energy use.

Common Applications:

Used in oil refineries to cool or heat hydrocarbons, in chemical plants for process temperature control, and in power stations for steam condensation and boiler efficiency. Food production uses them to pasteurize liquids, while HVAC systems apply them for climate regulation in industrial and commercial facilities.

EQUIPMENT

Filtration & Separation Units

Filtration and separation systems are essential components in modern industrial operations, ensuring the removal of contaminants from gases, liquids, and solids. These units enhance process reliability, protect sensitive downstream equipment, and support product quality by eliminating unwanted particles or substances. Depending on the industry and application, systems may involve mechanical, chemical, or membrane-based separation technologies.

Whether it’s filtering solids from fluids, separating oil from water, or purifying process air, these units play a critical role in maintaining operational efficiency and environmental compliance. Their modularity and adaptability make them suitable for integration into both new and existing production lines, with designs tailored to handle high flow rates, aggressive chemicals, or ultra-fine filtration.

Common Applications:

Used across a wide range of industries such as chemical processing, oil and gas refining, pharmaceuticals, food and beverage production, power generation, and water treatment — wherever the purity and consistency of process streams are essential to performance and safety.

EQUIPMENT

Compressors & Air Handling

Compressors and air handling systems are essential for providing air pressure and airflow in industrial applications. Compressors increase air or gas pressure for powering pneumatic tools and machinery, while air handling systems maintain air quality and pressure stability for optimal system performance. These systems are designed for various operational needs, from continuous operation with rotary screw compressors to high-pressure applications with piston compressors, or large air volumes handled by centrifugal compressors.

Air handling components such as dryers, filters, and receivers ensure clean, dry air for efficient operation and longevity of equipment. These systems are vital in industries requiring reliable air pressure and airflow for a range of processes.

Common Applications:

Compressors and air handling systems are used across industries like manufacturing, automotive, pharmaceuticals, and oil & gas. They power pneumatic tools, automated production lines, and air-driven machinery. Additionally, they are crucial for material conveying, packaging, and cooling systems in power generation.

EQUIPMENT

Electrical & Power Distribution

Electrical and power distribution equipment ensures the safe and efficient delivery of electricity within industrial systems. This category includes switchgear, transformers, motor control centers (MCCs), and uninterruptible power supply (UPS) systems. These components manage, distribute, and protect electrical power, ensuring consistent performance while safeguarding against faults. UPS systems offer backup power, preventing downtime during power interruptions.

These systems are integral to maintaining operational continuity and protecting sensitive equipment across a variety of industries.

Common Applications:

Used in power plants, manufacturing facilities, oil & gas operations, and large infrastructures, electrical distribution equipment ensures safe and reliable power supply, controls machinery, and provides emergency backup.

EQUIPMENT

Mixing & Blending

Mixing and blending equipment is essential in a variety of industries to combine different substances into a homogenous mixture. This category includes agitators, static mixers, and high-shear mixers. Agitators are commonly used for liquid-to-liquid mixing and are ideal for blending fluids of different viscosities. Static mixers, which operate without moving parts, are often used for continuous processes, providing efficient and consistent mixing. High-shear mixers, designed for intensive mixing, are particularly effective for emulsifying, dispersing, and homogenizing products in pharmaceutical, chemical, and food processing industries.

These systems improve the quality and consistency of products, reduce processing time, and ensure precise material formulation.

Common Applications:

Mixing and blending equipment is commonly used in the chemical, pharmaceutical, food and beverage, and cosmetics industries. These systems are used in processes such as product formulation, emulsification, homogenization, and the production of coatings, paints, and adhesives

EQUIPMENT

Process Skids & Modular

Process skids and modular systems are pre-assembled, compact units designed to streamline industrial processes. These systems integrate various components, such as piping, instrumentation, valves, and vessels, into a single, portable unit. Modular systems are designed for quick deployment and easy installation, significantly reducing on-site construction time and labor costs. They are ideal for industries that require flexible and scalable solutions, such as oil & gas, chemicals, and pharmaceuticals.

These systems provide cost-effective and efficient solutions for a wide range of processes, including chemical reactions, filtration, water treatment, and more.

Common Applications:

Process skids and modular systems are used in diverse industries, including oil & gas production, chemical processing, water treatment, and pharmaceuticals.

They are commonly applied for fluid handling, filtration, chemical reactions, and energy generation.

EQUIPMENT

Material Handling & Conveyor

Material handling and conveyor systems are essential for the transportation of raw materials, finished goods, and other materials within a production facility or across various industries. These systems include belt conveyors, screw conveyors, chain conveyors, and pneumatic conveyors, each designed to handle different types of materials and environments. Belt conveyors are commonly used for transporting bulk materials over long distances, while screw conveyors are ideal for moving granular or powdered substances. Pneumatic conveyors use air pressure to transport materials in enclosed pipelines, often used for delicate or lightweight materials.

These systems improve efficiency, safety, and productivity by automating material transport, reducing manual labor, and optimizing space utilization in production environments.

Common Applications:

Material handling and conveyor systems are widely used in manufacturing, mining, food processing, packaging, and logistics. They are applied in industries that require the transportation of raw materials, components, or finished products across different stages of production.

EQUIPMENT

Boilers, Burners & Steam

Boilers, burners, and steam generators are critical for steam production in various industrial applications. Boilers generate steam by heating water using fuel sources like gas, oil, or coal. Burners ensure efficient combustion, while steam generators provide compact solutions for steam generation. These systems are essential in industries that require heat for processing, heating, or power generation.

Modern designs prioritize energy efficiency, low emissions, and easy maintenance, while advanced control systems optimize performance and ensure environmental compliance.

Common Applications:

Used in power plants, chemical processing, food production, and manufacturing for steam-driven processes, energy recovery, and industrial heating.

EQUIPMENT

Tanks, Vessels & Storage

Tanks, vessels, and storage units are essential for safely storing and handling liquids, gases, and other materials across industries. These systems include pressure vessels, chemical storage tanks, and intermediate bulk containers (IBCs), designed to meet rigorous safety standards. Manufactured from durable materials like stainless steel and carbon steel, they are engineered to withstand challenging conditions, from extreme temperatures to high pressures.

These storage solutions are widely used in sectors like oil & gas, chemicals, pharmaceuticals, and food processing to ensure the safe transport, storage, and management of various substances.

Common Applications:

Used in industries such as chemical storage, oil & gas, pharmaceuticals, food & beverage, and water treatment for safe and efficient storage and transportation of liquids, gases, and solids.

Global Supply Integration

Ensuring Seamless Sourcing and Delivery Across Borders

Specialized Sourcing Solutions

We connect you with premium suppliers worldwide, ensuring access to high-quality products at competitive prices. Our tailored sourcing strategies are designed to meet your unique requirements, ensuring your products are sourced effectively, whether locally or globally.

Shipping & Freight Services

We provide efficient and secure transportation solutions to move goods across borders. Whether by sea, air, or land, our logistics services ensure safe, on-time delivery while minimizing costs. We focus on optimizing freight routes and ensuring the best shipping practices.

Logistics Tracking Systems

With our real-time logistics tracking systems, you gain full visibility into your shipments. This allows you to monitor the progress of deliveries, track inventory levels, and make adjustments as needed to ensure timely and accurate delivery.

Customs Brokerage Services

Navigating customs regulations can be complex, but our experts handle all customs clearance processes, ensuring compliance with local laws and minimizing delays. We streamline the process, managing paperwork and duties, so your goods move smoothly across borders.

Warehouse Management Systems (WMS)

Our Warehouse Management Systems optimize inventory control and order fulfillment. By using advanced WMS, we ensure accurate tracking of your goods and efficient space utilization, helping speed up the entire process from storage to final delivery.

Reliable Delivery Across Borders

We prioritize reliable delivery and timely transportation of goods. Our global supply integration services provide seamless and transparent delivery tracking, ensuring your products reach their destination on time. We manage everything from sourcing to the last mile.

Proudly powered by WordPress